ReCree8™ Resin

ReCree8™ Resin stands as Thinkpac’s innovative solution to Australia’s soft plastic waste challenge. Derived from recycled post-consumer soft plastics, this cutting-edge material is transformed into high-quality resin certified by the Global Recycled Standard (GRS). Embracing circular economy principles, ReCree8™ Resin not only minimizes environmental impact but also supports local recycling initiatives. By choosing ReCree8™ Resin, you opt for eco-friendly packaging solutions that prioritize sustainability without compromising on quality.

The Journey of ReCree8™ Resin

Pre-Consumer versus

Post-Consumer Recycling

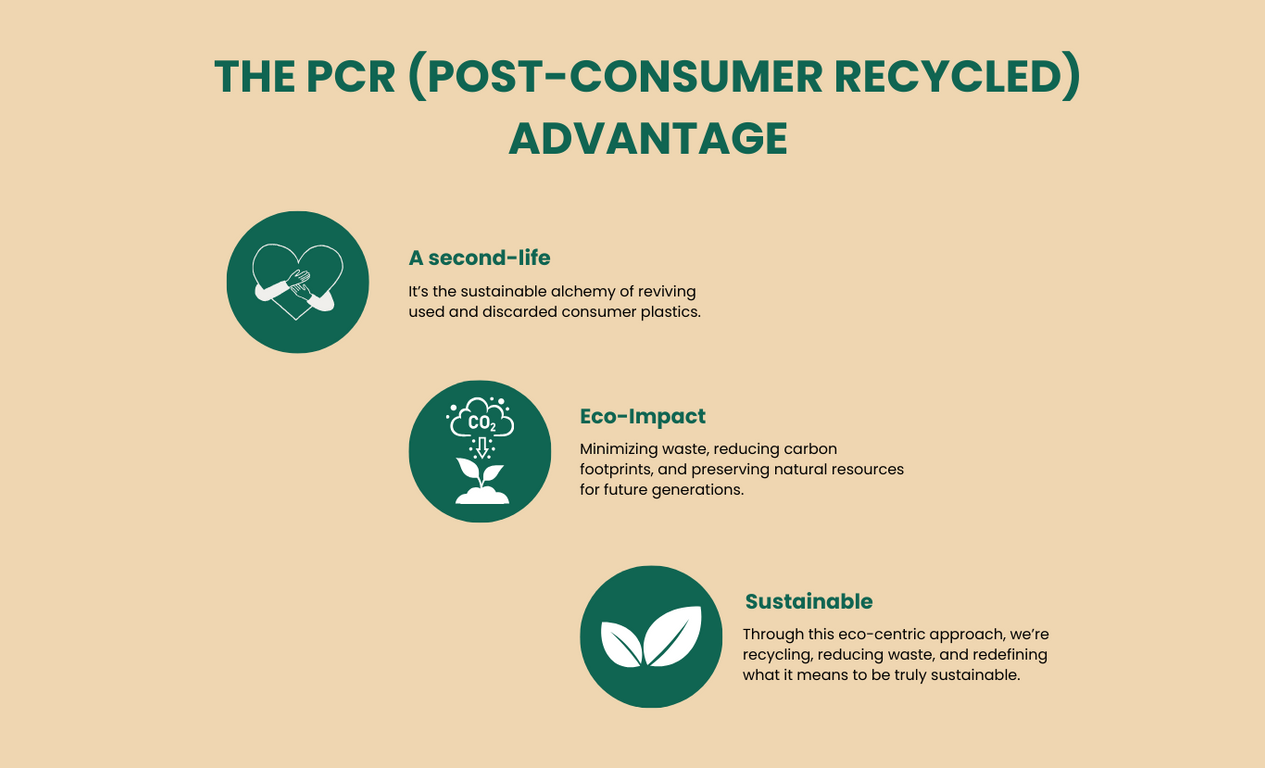

Many products on the market claim to contain “recycled plastics,” yet this terminology is frequently used to include pre-consumer plastics. Pre-consumer plastics are typically clean, unused scraps or factory wastage that would be recycled by the industry regardless as part of their standard operating processes.

Post-consumer plastics, on the other hand, are materials that have served their initial purpose in the hands of consumers and are then discarded. These are the plastics that, without thoughtful intervention, could clutter our landfills and choke our oceans.

At Thinkpac, we actively clear waste from our environment by focusing on recycling these post-consumer materials.

Giving Plastic ‘Waste’

a Second Chance

We put a lot of focus on post-consumer soft plastic ‘waste’ that is destined for landfills after they’ve served their original purpose.

Our unique recycling set up is the direct lifeline for these materials from ‘waste’ to product, providing them with a route back into the economy and away from landfills. We breathe new life into the mountains of ‘waste’ at our recycling facilities, giving them ‘a second chance’.

Crafting the Landmark

Recree8™ Resin

Our commitment to sustainability culminates to our landmark ReCree8™ resin.

ReCree8™ resin is a 100% post-consumer recycled resin that challenges the status quo, offering a second life to plastics that have completed their initial journey.

This isn’t just any resin; it’s a symbol of the circular economy, setting a benchmark in today’s marketplace.

When you choose ReCree8™ made products, you’re not just buying a product; you’re investing in a promise for a cleaner planet.

Revolutionising Packaging with ReCree8™ Resin

ReCree8™ Resin leads the way in sustainable packaging solutions, revolutionizing industry standards with its innovative approach. Made and recycled from post-consumer soft plastics waste, ReCree8™ Resin signifies a significant shift towards responsible packaging practices. By repurposing waste materials into high-quality resin, it not only reduces packaging waste but also fosters a circular economy model.

At Thinkpac, our dedication to sustainability extends beyond products; it’s a commitment to shaping a greener future. Explore our diverse range of sustainable packaging solutions, including our eco-friendly packaging products. Each collection offers innovative solutions designed to meet the unique needs of businesses while promoting environmental responsibility.

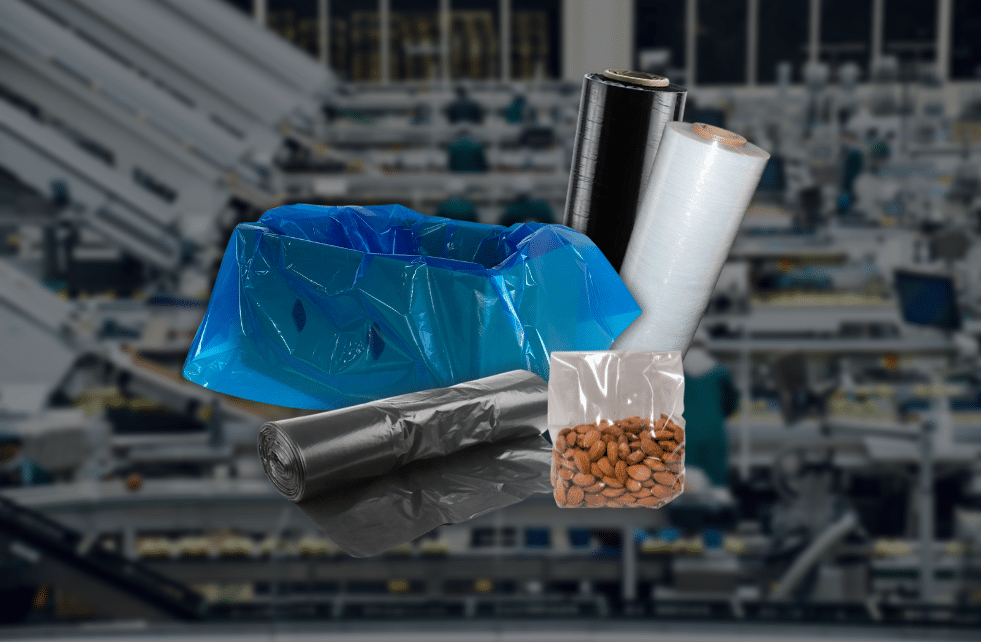

Sustainable Packaging

Our Sustainable Packaging features products with ReCree8 resin from recycled material, boosting recyclability and reducing waste. Explore eco-friendly bin liners, carry bags, and pallet top covers for robust performance and environmental stewardship.

Cleaning and Janitorial

Thinkpac's Cleaning and Janitorial range offers eco-friendly biodegradable bin liners, stretch film, nitrile and vinyl gloves, and cleaning wipes. These products support environmental goals and integrate seamlessly into daily operations.

Food Service Packaging

Thinkpac's Food Service Packaging includes sustainable freezer bags, LDPE bags, carton liners, and more, crafted for efficiency and environmental commitment. Our products, featuring ReCree8 resin, support recycling and circular economy practices.

Industrial Packaging Solutions

Thinkpac offers heavy-duty industrial packaging like stretch film, bin liners, and medical waste bags for optimal protection and sustainability. Explore our premium nitrile gloves, pallet covers, and poly bags for diverse industrial needs.

Disposable Apparel and PPE

Thinkpac's Disposable Apparel and PPE category offers ear muffs, safety goggles, gloves, aprons, hairnets, and medical masks for effective protection. Prioritize safety and sustainability with our comprehensive range of protective gear for various industries.

Custom Packaging

Thinkpac offers custom packaging tailored to your brand's needs, enhancing presence with unique sizes and styles. Consult our team for sustainable, innovative solutions that support your environmental goals.

ReCree8™ Resin Contributing to a Circular Economy

ReCree8™ Resin, developed by Thinkpac, stands as a beacon of sustainability in Australia’s packaging industry, actively contributing to the circular economy. By leveraging the innovative properties of resin, ReCree8™ facilitates the transition towards a more sustainable future through various strategies:

- ReCree8™ Resin incorporates recycled content obtained from post-consumer plastic waste, reducing reliance on virgin resources and creating a market for recycled plastics. This not only minimizes waste but also conserves valuable resources.

- ReCree8™ Resin promotes waste diversion and recycling by keeping materials (including landfill bound materials) out of landfills, providing opportunities for reuse, and giving used materials another life. By enabling the creation of products designed for multiple uses, ReCree8™ Resin actively promotes waste collection and supports the recycling industry, essential elements for fostering a circular economy.

- Incorporating ReCree8™ Resin into product manufacturing not only produces sustainable solutions but also generates demand for soft plastic waste, a critical component of the circular economy.

Through these initiatives, ReCree8™ Resin plays a vital role in driving circular economy principles, reducing plastic waste, and promoting resource conservation.

Why use ReCree8™ Resin

A Pledge to

Quality and Sustainability

Our recycling process isn’t just effective; it’s certified. With an ISO 14001 accreditation, our recycling facility meets stringent environmental management standards. This ensures that every step we take, from collection to reprocessing, adheres to an internationally recognized framework that prioritizes sustainability, efficiency, and environmental responsibility.

ReCree8™ resin also carries the Global Recycled Standard (GRS) certification, affirming that ReCree8™ resin is indeed made from 100% post-consumer recycled content. GRS certification isn’t just a label; it’s a globally recognized mark of traceability, environmental principles, social responsibility, and chemical restrictions.

Decades of Dedication

The journey to ReCree8™ resins is backed by over 25 years of experience in the recycling industry. It reflects significant investments in both human and machinery capital. Our team isn’t just knowledgeable; they’re pioneers in compliance, understanding local environmental regulations, and committed to producing high-quality resins that serve their purpose beautifully.

Designed for a Purpose

ReCree8™ resin is predominantly crafted to transform into packaging items – a “bag to bag” or “film to film” solution. It’s the brainchild of Thinkpac’s team that’s been at the forefront of the soft plastic packaging (manufacturing) industry for over 35 years. Our expertise ensures that ReCree8™ resins aren’t just versatile; it’s specifically engineered for the packaging world, embodying strength, flexibility, and sustainability in every fiber.

Introduction to ReCree8™ Resin

The ReCree8™ Manufacturing Process

At Thinkpac, our commitment to sustainability begins with our innovative and meticulous manufacturing process for ReCree8™ Resin. From waste collection to final product realization, every step is carefully designed to minimize environmental impact and maximize resource efficiency.

Waste Collection

Our journey towards sustainability starts with the meticulous collection of post-consumer soft plastics. Through partnerships with businesses, we gather soft plastics with purpose, diverting them from landfills and giving them a new life.

PE Sorting and Separation

Precision is paramount in our manufacturing process. Through our meticulous sorting techniques, we ensure that only polyethylene (PE) plastics enter our process. This meticulous sorting not only ensures the quality of our raw materials but also enhances the efficiency of our production process

Purification via Washing

Once sorted, the soft plastics undergo a thorough purification process. Employing advanced washing techniques, we cleanse the plastics of any contaminants, preparing them for transformation into ReCree8™ Resin. This purification step is essential to ensure the integrity and purity of our final product.

Resin Compounding

Our compounding process is where science meets art. Through precise blending and refining, we transform the purified plastics into ReCree8™ Resins. This proprietary process allows us to create high-quality resins with consistent properties, ready to be molded into a wide range of sustainable products.

Final Product Realization

Here, imagination takes physical form. Our skilled craftsmen and advanced manufacturing technologies transform ReCree8™ Resins into new, resilient, and sustainable products. From packaging materials, each product reflects our commitment to sustainability and innovation.

At Thinkpac, our manufacturing process for ReCree8™ Resin exemplifies our dedication to sustainability and environmental stewardship. By transforming waste into valuable resources, we are not only reducing our environmental footprint but also creating a brighter and more sustainable future for generations to come.

Versatility in

Application

Thinkpac’s ReCree8 Resin offers unparalleled versatility, extending beyond traditional packaging solutions. Our commitment to sustainability drives innovation, leading to a comprehensive range of applications:

- Reusable Carry Bags: Eco-friendly alternatives for shopping and promotional purposes.

- Produce Rolls: Sustainable packaging for fruits, vegetables, and perishable items.

- Garbage Bags: Durable solutions for waste disposal in households and industries.

- Skip Bin Liners: Hygienic liners for construction, renovation, and demolition waste.

- Medical Waste Bags: Compliant options for safe medical waste disposal.

- Carton Liners: Moisture-resistant protection for stored and transported goods.

- Crate Liners: Cleanliness and protection for agricultural and logistic operations.

- Pallet Stretch Film: Secure wrapping solutions for hand and machine applications.

- Pallet Top Covers: Shielding palletized goods from dust, moisture, and UV exposure.

- Tarpaulin: Can be used in making tarps (large sheets of strong, flexible, waterproof material) for a wide range of applications.

- And more!

Explore the endless possibilities of ReCree8 Resin and join us in shaping a sustainable future.

Associations or Certifications